Experiments with Multi-Agent Systems in Irregular Folded Structure

- Parts of this work are being presented at and published in the proceedings of ICGG2014 and KES2014 -

Aim

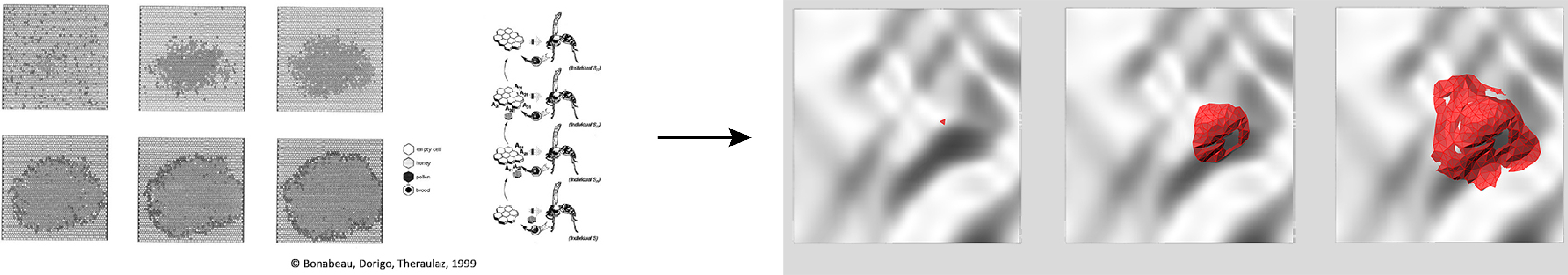

In the presented work it was attempted to find a way to utilize two different bionic principles for an architectural purpose: the mechanical-physical process of folding and the emergence of intelligent, or at least optimized behavior observed in social collaborative swarms of animals, such as ant colonies, termites and schools of fish. As a sufficiently complex task, we intended to regenerate an arbitrary free form surface with such a multi-agent system.

To do so, we established, geometrically described, optimized and programmed a physical prototype. The setup at hand is a foldable structure of simple, interconnected robotic agents. They are located on the edges of a virtual triangular mesh and control the angles between adjacent facets. This structure is supposed to have the capacity to reshape itself in a self-directed manner. The preliminary objective was to let the structure approximate a certain target shape. Beyond this, more general concepts for the application of the system were investigated on.

This robotic device was named "Kingfisher". Its functional foundation is Bionics.

Below you can find information about the concept of the structure, its geometrical foundations, and the prototypical realisation.

Concept

The core question we tried to answer in this project was: Is there a mechanism comprised of simple agents which are able to interact in order to regenerate a (predefined) free form surface. The basic design and functioning of such a mechanism forms the essential conceptual question of this project. In an early stage, a butterfly-like layout was proposed, in which agents form a folded structure and change the angles between adjacent facets over folding edges. Using this method, each agent is able to modify the apeareance of the overall structure by just adjusting a single angle value. The conceptual idea can briefly be summarized in the short video clip on the left.

Geometry - Standardization vs. Smoothness

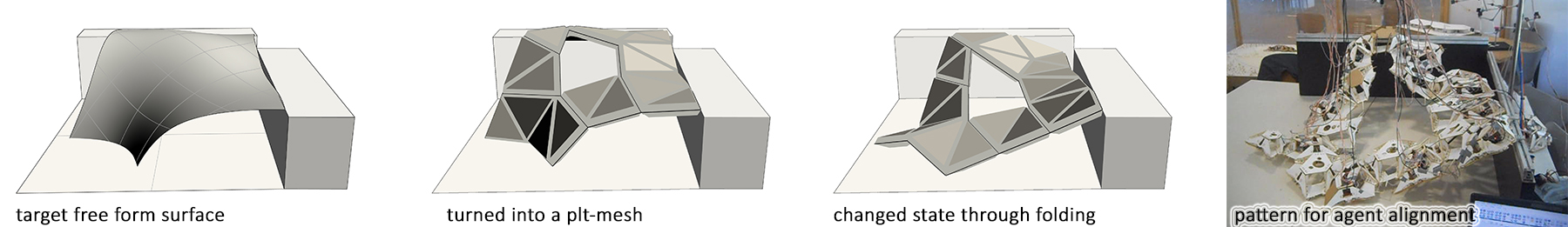

The geometrical abstraction of the underlying folding pattern of our proposed setup is represented by a triangular polygon mesh, in which the folding agents are located on the inner mesh edges. Thus the generation of the folding pattern represents an issue of free form discretisation.

Since we intended to serve an architectural purpose, certain preconditions had to be set, derived from the requirements of constructability and maneuvrability of the device:

To establish a construction kit, which is affordable and easy to produce, we have to maximise the degree of repetition of components the system is made of. A conventional free form triangulation, which in general produces nothing but unique edge lengths, would have forced us to individually draw and produce every piece of the frame. Thus it proved very advisable to find a way to triangulate free form surfaces only using a limited variety of unique pieces - respective: a limited variety of lengths in the mesh's edges.

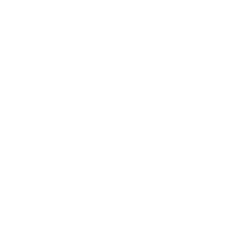

In respect to the constraints of limitation and perforation in triangulation described above the underlying geometric model was called the PLT-Mesh - the perforated, limited, triangular mesh of the rank x, in which x describes the amount of unique edge lengths utilized. The image on the left shows a plt-mesh of rank 4. Further information about the geometric properties of the plt-mesh can be found in the publication for ICGG2014

Since we intended to serve an architectural purpose, certain preconditions had to be set, derived from the requirements of constructability and maneuvrability of the device:

To establish a construction kit, which is affordable and easy to produce, we have to maximise the degree of repetition of components the system is made of. A conventional free form triangulation, which in general produces nothing but unique edge lengths, would have forced us to individually draw and produce every piece of the frame. Thus it proved very advisable to find a way to triangulate free form surfaces only using a limited variety of unique pieces - respective: a limited variety of lengths in the mesh's edges.

In respect to the constraints of limitation and perforation in triangulation described above the underlying geometric model was called the PLT-Mesh - the perforated, limited, triangular mesh of the rank x, in which x describes the amount of unique edge lengths utilized. The image on the left shows a plt-mesh of rank 4. Further information about the geometric properties of the plt-mesh can be found in the publication for ICGG2014

Triangulation

The algorithm established to generate the folding pattern was suppsoed to tap the full potential of a PLT-Mesh. It is based on the idea of setting an arbitrary triangle as a "seed" on the surface to be discretized and make the other triangles "grow" over the free form surface, starting from this seed and always adapting to local situations on the free form surface. This method is inspired by and similar to the behavior that wasps show when choosing the most enclosed comb cell to fill when building their nests.

This method is described more in detail in the section "Limited Triangulation" in "Projects" on this website.

This method is described more in detail in the section "Limited Triangulation" in "Projects" on this website.

certain iterative steps in the progress of free form discretisation

Simulation

To simulate the physical behavior of a folding plt-mesh, Rhino 5 Grasshopper and the physics engine Kangaroo were used. On the left you can see the collapse and re-erection of a plt-mesh of rank 4. In the first part of the clip (until it is completely collapsed) there is no other force than gravity applied. To re-erect the structur, an actual hinge force was applied over each folding edge, pushing towards the initial angle state.

Since the engine was actually designed to simulate flexible mesh relaxation (a particle-spring engine) it is hardly possible to simulate completely rigid edge, without any length deviation during simulation. This disadvantage, however, was used to measure the stress in each agent following from jams and agents blocking each other during the folding process. By recording the length deviations in each agent and turning these numbers into serial data curves it is possible to interpret peaks and bumps within these curves as cracks that would appear during folding caused by jams.

Furthermore the serial data curves of the individual angle values could be recorded in a simulation and turned into actual control curves for the robotic agents to follow. With this method, the device is able to re-execute a previousy recorded computer simulation in the real world.

See more information about this aspect in the full work.

Since the engine was actually designed to simulate flexible mesh relaxation (a particle-spring engine) it is hardly possible to simulate completely rigid edge, without any length deviation during simulation. This disadvantage, however, was used to measure the stress in each agent following from jams and agents blocking each other during the folding process. By recording the length deviations in each agent and turning these numbers into serial data curves it is possible to interpret peaks and bumps within these curves as cracks that would appear during folding caused by jams.

Furthermore the serial data curves of the individual angle values could be recorded in a simulation and turned into actual control curves for the robotic agents to follow. With this method, the device is able to re-execute a previousy recorded computer simulation in the real world.

See more information about this aspect in the full work.

Prototypes

After the basic idea of the model's design was elaborated, three consecutive prototypes were established and built in order to improve their performance.

The very first motorized prototype was an assembly of two agents mount to three triangle facet frames. It mainly consists of MDF and is motorized with a 12V model train motor "Motraxx X-Slot Race 143". It was controlled using an Arduino Uno and the plug-in Firefly for Grasshopper in Rhino 5. The major insight this model gave, was that the utilized MDF was

to heavy for the relatively weak motor. Furthermore it revealed the major importance of

the shield angle of the triangle frame, since it directly affects the leverage and therefore the power transition. For detailed information about the construction of this prototype view the entire submission.

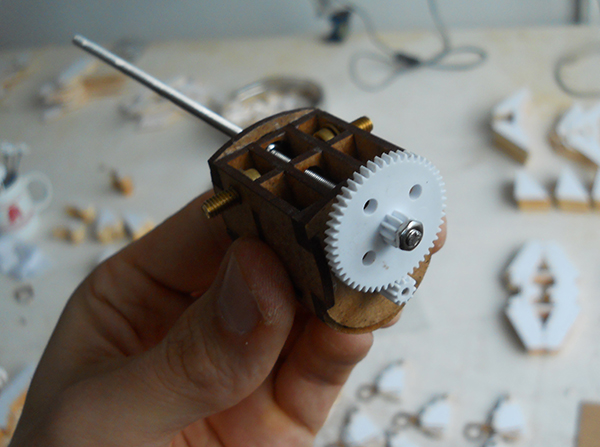

The second prototype was improved in respect to the knowledge gained in Kingfisher 0.1. It mostly consists of a much lighter foam board material and is empowered with the stronger "Motraxx X-Slot 283 Tuning". In contrary to its predecessor it is empowered with a 12 V operating voltage. This is made possible by employing a motor control chip based on the L293 chip with an operating current of up to 500mA per channel. Furthermore the basic layout and sections were improved. Due to these changes the model is able to lift itself off the ground and showed a much higher agility in general.

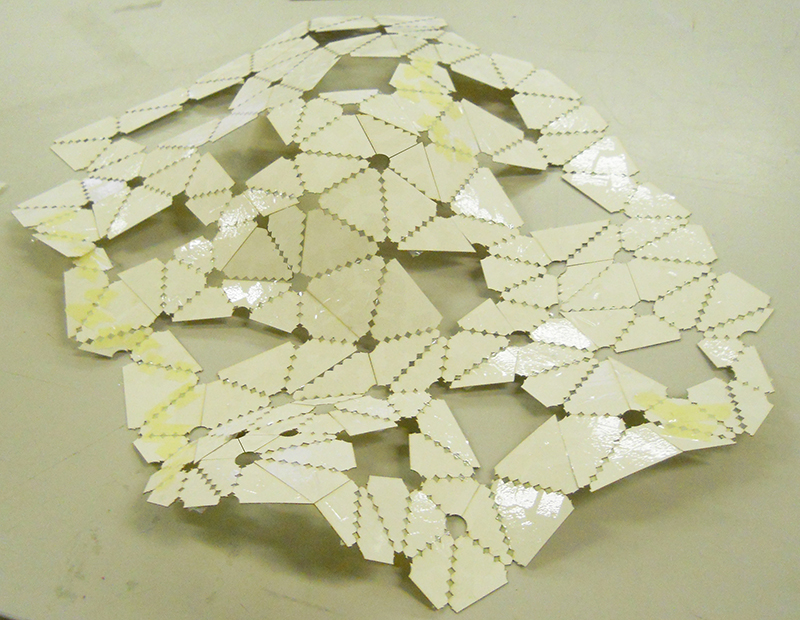

In the third and last prototype some major improvements were made: the empowering unit was speerated from the triangular frame which interconnects the agents. It is furthermore equipped with a gear box with a transition ratio of 1:4 (figure 9), a stronger motor ("Johnson 20543" with 130 Nmm torque) and a potentiometer mounted to

the frames giving a feedback of the rotation and angular state in the agent. Its highly stressed parts (e.g. the mount of the motors) are made of stable MDF while the rest is made of lighter foam board.

In this prototype we used motor control shields based on the L298N chip to receive a powerful operating voltage of 12V and up to 2A current per channel (two channels).

In this prototype we used motor control shields based on the L298N chip to receive a powerful operating voltage of 12V and up to 2A current per channel (two channels).

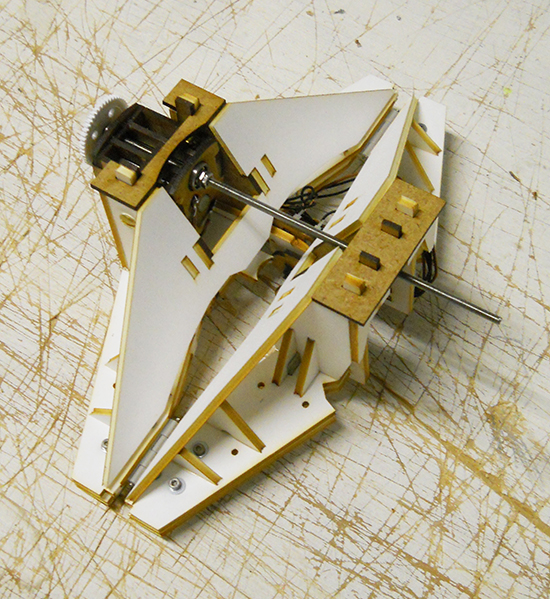

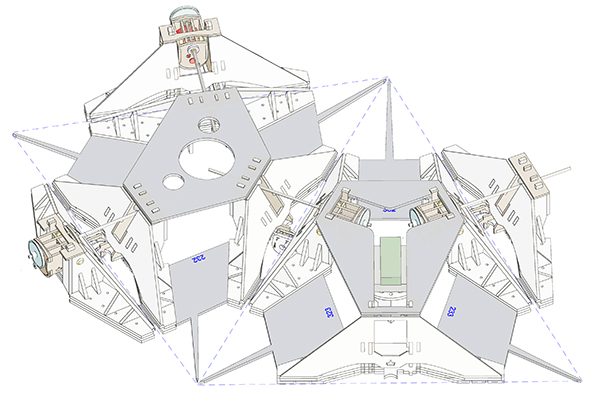

After the final prototype was elaborated, the design was applied to a larger composition in which 22 agents were combined. To find this alignment a previously defined target surface was triangulated using the Limited triangulation algorithm.

See the final prototype's behavior when it tries to reach its target surface. In this clip it tries to follow a previously recorded program in the form of 10-bit integer arrays implemented in the individual code of each agent (the method used is described here). The lack in strength and mechanical resistance of the material causes the robot to fail to reach its destined state.

Kingfisher - Experiments with Multiagentsystems in Irregular Folded Structure from Benjamin Felbrich on Vimeo.

Full Work

What do you want to see?

Full text as a .pdf-file | Slide show of the final presentation | Foto slide show of the assembly | ICGG2014 publication | KES publication