Force Flow Shape Optimization for Earthquake Resilience

Situation

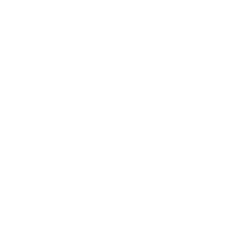

On January 26th 2001 an earthquake of magnitude 7.7 shattered the earth in the region of Bhuj in the state of Gujarat, India. Lasting over two minutes the earthquake killed about 20,000 people, injured about 167,000 and destroyed nearly 400,000 homes. An epic tragedy which left a whole country in shock. In 2004 the government of Gujarat appointed the planners of Vastu Shilpa Consultants to envision an earthquake memorial. The concept was to turn an extensvie arid hill in this region into an earthquake memorial forrest, planting one tree for every victim and using traditional, newly built step wells to water these trees.

More information about this memorial can be found here and here. The recent progress in building the water collecting wells can be seen in the Google map of the site:

Idea of a Museum

- idea developed by VSC -

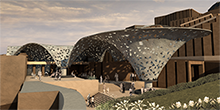

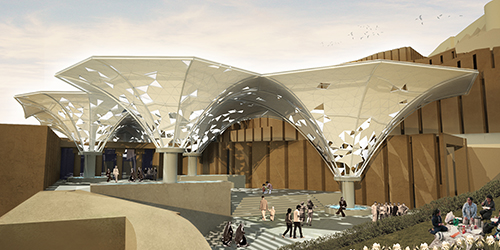

In addition to this forest a memorial museum was proposed dedicated to the culture of Bhuj, earthquakes in general and specifically to the incident in 2001. Its location was chosen to be on the slope of the hill in the south east of the site. The heavily sloping site and the threads of the earthquake hazard zone five (the highest category) form special challenges in this project.

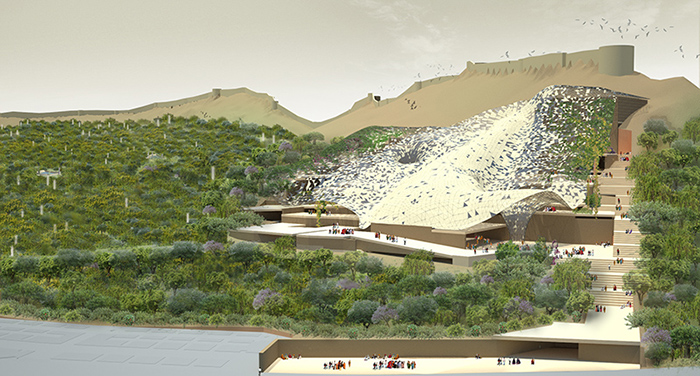

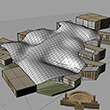

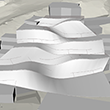

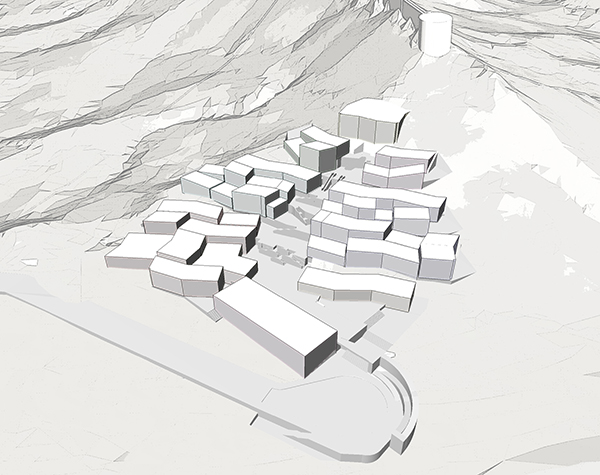

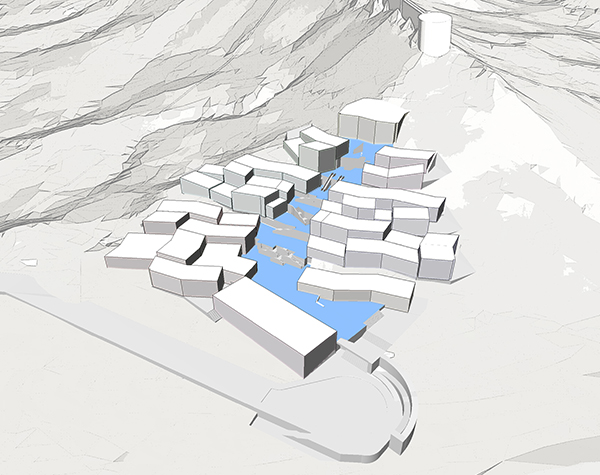

The museum's space allocation plan was split into several independent functional and thematic units, housed in tilted concrete boxes meandering up the hill. In addition to the main movement the visitors take through the boxes, an access "spine" was kept free in the center of the museum to form a direct connection between its different parts. Due to the slope in the site, this access path has to climb up the hill. To protect visitors from the burning desert sun or heavy rain during monsoon a roofing structure was intended to be built over this spine.

boxes set into the hill

Spine (blue) to be covered

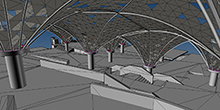

Establishing the Concept

As a reminiscence to the water-collecting step wells scattered over the hill, the museum was to be covered with an organically shaped structure with funnel-like dimples. These dimples would serve to collect water and form the pillars for the rest of the roof structure to rest on.

The design of this roof structure was elaborated in two more or less seperate branches:

#1: design of the large overall shape of the roof

#2: find a way to subdivide / panelize this form

For both aspects the respective tools had to be established using Rhino 4 and Grasshopper.

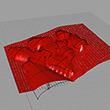

The first conceptual stage mainly employed relatively arbitrary free form to cover the entire museum.

However, essential problems with the force flow became apparent. Especially with respect to the high risk of earthquakes in this region, a more sophisticated load bearing structure had to be found.

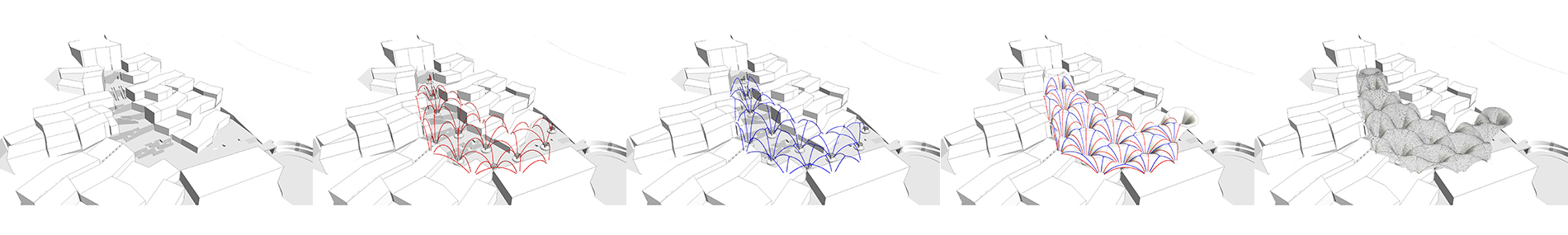

The following pictures give a scematic chronologic overview of how the 3D model developed. Important steps in the design progress are highlighted in a higher opacity.

- click -

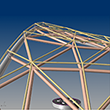

How to build a structure that is both visually pleasing and resilient against heavy earthquakes? In the beginning of the 20th century Antoni Gaudi revolutionized the way architects plan complex structure by employing upside down force models. Through sophisticated computation it is now possible to realistically simulate this behavior. This gives us as planners the opportunity to tremendously reduce cost when planning heavily stressed structure, and the freedom to play with form, simulate how it would behave and minimize risk when actually erecting it. By simulating and "upward" hanging chain model, it was possible to avoid momentums in the arches foundations and thereby establish a very resilient structure.

The following movie clips show the erection of such a structure with the tools of computation. The first one gives an overview over the basic idea.

Smriti Van Earthquake Memorial Museum from Benjamin Felbrich on Vimeo.

The following three videos describe the generation of the structure more detailed and document the work progress.

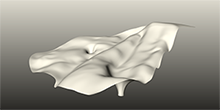

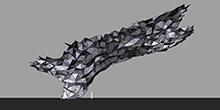

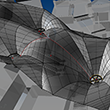

The first video below shows the simulation of a three pointed catenray dome, an essential structural component of the load bearing assembly. Its shape was optimized to converge to a predefined sloping plane. This measurement had to be implemented to find a shape pleasing to the eye and to give the structure a distinctly ordered appearance.

The structure was elaborated using Rhino 4, Grasshopper and the physical engine Kangaroo. Due to the tremendous threads in this earthquake hazard zone 5, the rather complicated geometry of the cosinus hyperbolicus coshx (catenary) had to be employed instead of the much simpler, almost similar parabola curve. To handle this geometry the Galapagos solver component in the Grasshopper GUI environment was utilized.

Smriti Van Earthquake Memorial Museum from Benjamin Felbrich on Vimeo.

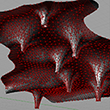

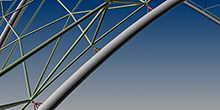

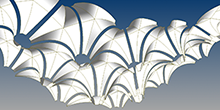

After the basic geometry, the curves for the main load bearing steel pipes and the resulting surfaces were found, the geometry had to be discretized to form panels of a buildable size. The video below shows this progress.

To cope with the conflict between strict conditions in the triangulation (fixed outer nodes, offset meshes to provide intervals for construction) and the limited computational power of a single processing unit, this procedure had to be subdivided into consecutive steps rather than computing all panels at once. To do so, the geometry was disassembled into its components (single free form surfaces in the form of a hanging pizza slices) and treated step by step.

Smriti Van Earthquake Memorial Museum from Benjamin Felbrich on Vimeo.

In the last step, all the parts generated in the steps described above had to be documented into .dwg files. The automation of this procedure saved a lot of time and kept it flexible to changes in the design process. The video below shows one main method: A script examines every single curve of the main load bearing steel pipes, projects it to the floor, measures and draws it in standard drawing panels and assigns distinct indices.

Another method (not shown in the video) did the same to the triangular panels which can be seen in the previous clip.

Smriti Van Earthquake Memorial Museum from Benjamin Felbrich on Vimeo.

With the methods shown above it was possible to change the location of main pillars even in the last steps of the design process. Up to two weeks prior to handing in the tender drawings we were able to make changes and adapt to changing conditions derived from changes in the design of the other parts of the building (changing access paths, structural improvements in the foundation